What is a Pad Eye Tester?

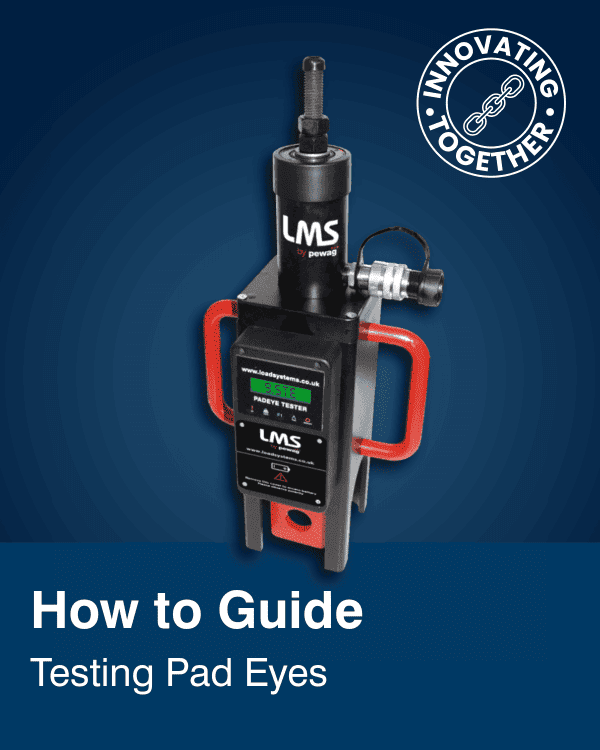

A Pad Eye Tester is a lightweight, portable device that uses hydraulics to apply force to a pad eye and measure its response. It is compatible with most pad eye sizes within its capacity and provides real-time wireless readings on a built-in digital display. This allows users to monitor the load exerted on the pad eye, ensuring tests are precise and safe.

Easy to transport, the Pad Eye Tester can be quickly taken from one testing location to another, making it ideal for regular use across different applications, both offshore and onshore.

Digital Readout and Connectivity

A key differentiator of the LMS Digital Pad Eye Tester compared with more basic mechanical testers is its onboard digital display, which provides load readings directly in multiple units — including tonnes, US tons, pounds and kilograms.

The digital system can also support data transmission and logging via optional Bluetooth connectivity, allowing readings to be recorded on a mobile phone, tablet or laptop. Additionally, the unit can transmit data to a wireless handheld display.

This functionality supports more efficient testing by eliminating manual load calculations and reduces the need for separate measuring instruments.

Equipment List

- 1 x Padeye tester available in 10te & 30te complete with threaded rod and jaw

- 1x Pump

- 1x Collar Set to match Pin size

- 1x Pin size 1

- 1x Pin size 2

- 1x Pin size 3

- 1x Pin size 4

- 1x Pin size 5

- 1x Hose (Not Pictured)

Getting Started

The Pad Eye Tester is supplied with alkaline batteries as standard. Replacing batteries is simple – just remove the four screws on the front cover to insert new ones.

Step-by-Step Guide to Testing Pad Eyes

Prepare the Unit

Place the Pad Eye Tester on a stable, flat surface over the pad eye you wish to test. Ensure that the unit is positioned correctly to allow even load distribution during testing.

Adjust the Jaw Height

Use the nuts on the threaded rod at the top of the tester to adjust the jaw height. Once set, insert a pin through both the jaw and the pad eye to secure the setup.

Power On and Zero the Display

Turn on the Pad Eye Tester. If the display shows any residual load before testing, press the zero button to reset the reading to zero.

Apply Load

Gradually increase the load on the pad eye by operating the hydraulic pump. Monitor the display carefully to ensure the load does not exceed the pad eye’s rated capacity.

Use Spacers if Necessary

For pad eyes mounted on uneven surfaces, spacers can be used to ensure even load distribution. This helps prevent inaccurate readings or damage to the pad eye during testing.

Secure the Unit

Once the setup is complete, lock the unit in place to maintain stability throughout the test.

Typical Setups

Wall-Mounted Pad eye: The tester can be mounted directly on pad eyes attached to walls or structural surfaces.

Padeye unit mounted on wall

Pin-Based Setup: Pins can be used to secure the jaw and pad eye for consistent load application.

Unit with pins placed under load

Hydraulic Pump Operation: The integrated pump provides controlled load application, ensuring precise testing results.

Exerting load using hydraulic pump

Example Setups

Using spacers for even load distribution

Unit locked in place

Construction and Accessories

The tester uses a two-speed hand pump with a locking handle, enabling controlled application of the hydraulic load. A 10 ft polyurethane hose with quick couplers is supplied, allowing flexible positioning of the pad eye tester relative to the pump.

The device is supplied proof-tested and calibrated before delivery. Carry cases are included for transport and storage, helping protect the unit when moving between sites.

Field Use and Practical Considerations

Because the tester can be used in upright, inverted or horizontal orientations, users can adapt it to a wide range of installation positions without additional fixtures or supports.

The tester’s adjustable jaw height, set using the threaded rod, lets operators align the tester with pad eye pins of varying heights, helping ensure accurate load application across different pad eye configurations.

Calibration and Maintenance

Units are supplied proof tested to 125% and calibrated, with calibration certificates supplied as required. Regular calibration according to site or project quality systems will maintain accuracy and traceability. Calibration certificates are valid for 12 months.

Safety First

Always follow the manufacturer’s instructions, check the condition of your pad eye before testing, and never exceed the rated capacity.

Keep hydraulic pumps away from flames and direct heat. Avoid damaging the hydraulic hose and always route hoses so they are free from sharp bends and kinks. Using a bent or kinked hose can cause severe back-pressure and may lead to hose failure.

Never lift or carry hydraulic components by the hose or any hoses connected to them. Do not handle a pressurised hydraulic hose.

All operators must ensure that the required personal protective equipment, as specified by their employer, is worn when operating hydraulic equipment. All relevant risk assessments should be completed prior to use.

Summary

Testing pad eyes doesn’t need to be complicated. With the Pad Eye Tester, users can quickly and accurately verify the safety of pad eyes by following the step-by-step guide. This helps to prevent bending, breakage or equipment failure.