- Understanding the Hazards of Decommissioning

- How Load Monitoring Supports Safer Operations

- Applications in Offshore and Onshore Decommissioning

- Data Logging for Compliance and Analysis

- Conclusion

As industrial facilities and offshore structures reach the end of their operational lives, safe and efficient decommissioning becomes a top priority. From dismantling oil platforms to removing heavy equipment onshore, every phase involves critical lifting and structural support operations. Accurate load monitoring plays a central role in mitigating risks, ensuring compliance, and protecting both personnel and infrastructure.

Understanding the Hazards of Decommissioning

Decommissioning presents unique challenges not found in routine lifting operations. Structures may be corroded, weight distributions uneven, or environmental conditions unpredictable. Whether offshore in high seas or onshore in confined facilities, incorrect load handling can lead to catastrophic failures.

Key hazards include:

- Unexpected load shifts during disassembly

- Structural weaknesses in ageing infrastructure

- Limited headroom or access in congested environments

- Uncertain centre of gravity in dismantled components

How Load Monitoring Supports Safer Operations

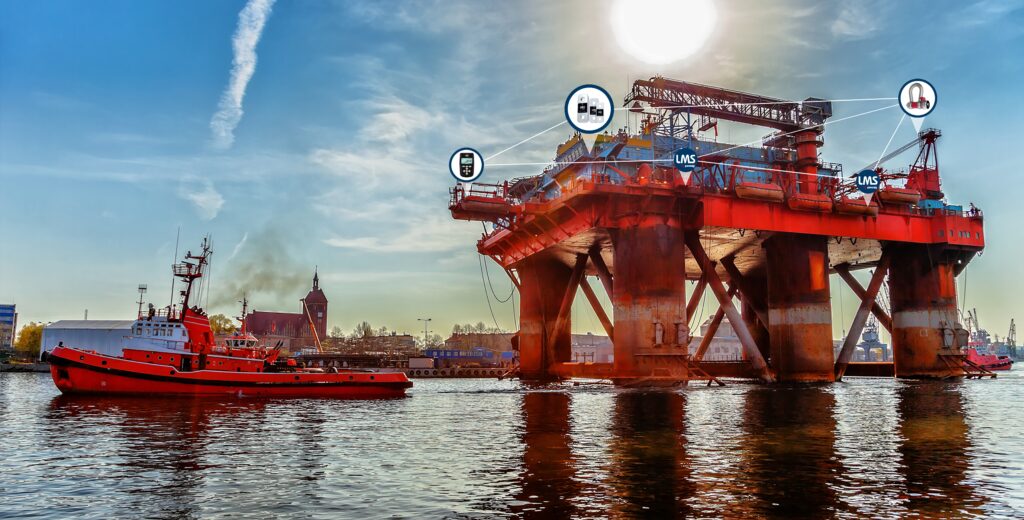

Load monitoring systems provide real-time data on tension, weight, and structural force, allowing engineers and operators to react swiftly to changing conditions. LMS wireless load cells, including load links, shackles, and running line tensiometers, are designed for rugged conditions and easy deployment — critical when time, safety, and accuracy matter most.

Key benefits include:

- Real-time monitoring to detect overloads or asymmetrical lifts

- Predictable data for planning safe disassembly sequences

- Wireless transmission that eliminates trip hazards and simplifies rigging

- Compatibility with subsea and ATEX-rated environments

Applications in Offshore and Onshore Decommissioning

In offshore environments, LMS systems support topside and subsea activities including module lifting, anchor recovery, and conductor removal. Wireless load links offer up to 800m transmission range, allowing teams to monitor operations from safe locations.

Onshore, load monitoring is used for dismantling heavy industrial assets such as cranes, storage tanks, or process vessels. Load pin shackles are ideal where space is limited, and lifting accuracy is critical.

Data Logging for Compliance and Analysis

Beyond operational safety, decommissioning projects demand rigorous documentation. LMS’s advanced logging tools record load data for compliance with safety regulations, auditing, and post-project analysis.

Key features include:

- Browser-based access via PC, tablet, or smartphone

- Time-stamped data logging for up to 100 devices

- Exportable reports in JSON or CSV format

- Centre of Gravity (COG) tools for complex lifts

Conclusion

Decommissioning projects represent some of the most technically demanding operations across multiple industries. With dynamic risks and unpredictable conditions, reliable load monitoring becomes an essential line of defense. LMS systems empower operators with the data and tools they need to execute lifts with precision, document performance, and protect people and assets every step of the way.

Whether dismantling a North Sea oil platform or deconstructing an aging power facility, load monitoring is more than an operational aid — it’s a safety imperative.