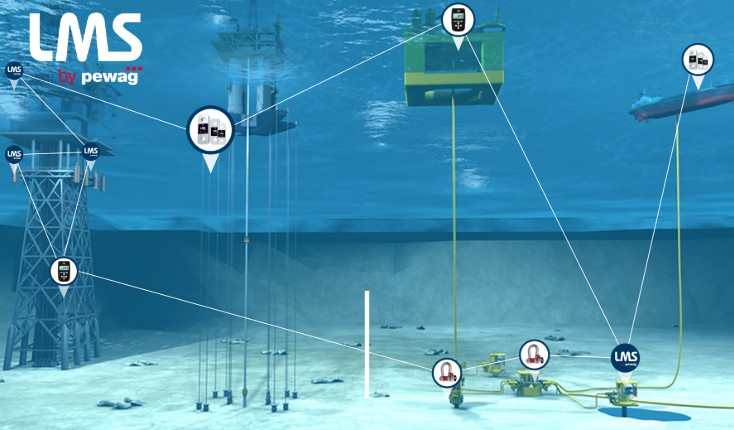

The subsea environment is among the most demanding in the world, and that’s especially true when it comes to load monitoring.

Whether you’re working on offshore platforms or subsea construction, understanding and managing forces beneath the waves is essential for safety, efficiency, and success.

At LMS, with over 50 years’ experience in specialist load monitoring systems, we’ve seen firsthand the challenges that come with subsea projects. From shallow cable assisted setups to deepwater deployments requiring acoustic transmission, we continue to innovate and customise load monitoring equipment that meets the unique demands of each job.

Here are some of the key challenges – and how we tackle them

Depth: The deeper the water, the tougher the job

Water depth is one of the most critical factors in subsea load monitoring. The first thing we ask when we have a new customer enquiry is – ‘how deep is this project?’ At relatively shallow depths (up to about 300 metres), it’s much easier and more cost effective to use cabled connections to transfer load data to the surface. These signals can be converted wirelessly and transmitted to a range of modular devices to those working topside.

However, we still have to work through some solutions to challenges with cables. On vessels with propellers and other moving parts, there’s a risk of cables becoming entangled or damaged. Plus, when you’re operating at depths of around 1,000 metres or more, the cost and complexity of cabling grows significantly. The signal integrity must be carefully managed over that distance, which requires the right technology and a wealth of practical experience, both of which LMS provides.

Power Struggles: Finding a smart solution to cables

When cables aren’t an option, we get creative and start thinking out of the box!

One effective approach involves load cells with built-in LED displays. Designed to be read by ROVs (Remotely Operated Vehicles), these displays are activated by light and stay illuminated long enough for topside teams to capture readings via onboard cameras. It’s a smart workaround, but it too comes with its own challenge – battery power. Creating a standalone load cell with enough energy to power a high brightness display isn’t easy, and battery size can quickly drive up costs.

Surviving the harsh subsea environment

Another innovation lies in in-built logging systems. For longer term subsea tests, sometimes running for several months at a time, customers need load cells that can reliably record millions of data points – we recently had a customer requiring analysis of 16 million readings! The challenge here is balancing low power hardware with high capacity memory, all while trusting that the system is reliable and strong enough to survive harsh underwater conditions.

Looking ahead

Acoustic technology is gaining traction in subsea load monitoring and is a method we receive an increasing amount of customer requests for. By sending signals from a load cell acoustically through the water (much like a submarine would) to a receiver on or near the vessel, we eliminate the need for physical cabling altogether.

The acoustic method requires a bigger team effort between load monitoring engineers and acoustic specialists. Everything from signal interference (caused by bubbles or moving parts) to positional accuracy must be considered. It’s an exciting area, and one that LMS is actively exploring as part of our commitment to staying at the cutting edge of load monitoring.

Innovative technology developments

Subsea equipment doesn’t just face moisture; it faces immense pressure. For high capacity load cells (like a 100-tonne unit), deepwater pressure isn’t typically a problem. But when the application requires a smaller load cell – say a 2-tonne pin type load cell – design becomes far trickier. The deeper it goes, the more the water pressure can compromise wall strength and calibration accuracy.

Our team draws on decades of experience to ensure every load cell is designed to withstand its operating environment. Every piece of equipment is stainless steel, corrosion resistant, and rigorously tested to meet both topside and subsea lifting regulations and safety factors.

At LMS, we specialise in designing, manufacturing, and renting out custom systems that fit your precise needs. From running line tensiometers to instrument calibration services, everything we do is backed by our proven track record in problem solving and adaptability.

Subsea industries are changing fast, and so are we. Whether it’s integrating acoustic communication, extending our rental stock with large capacity load links, or refining the battery life of subsea sensors, we’re always looking to improve.

Our process is simple but effective – we listen to our customers, learn from every project, and continually refine our technology to be smarter, tougher, and more efficient.

Want to learn more?

Whether you’re planning your next offshore project or need expert advice on load monitoring options, our team is here to help.